Moulding

It is durable, functional, multipurpose, insulating, paintable and can be perfectly integrated with all materials.

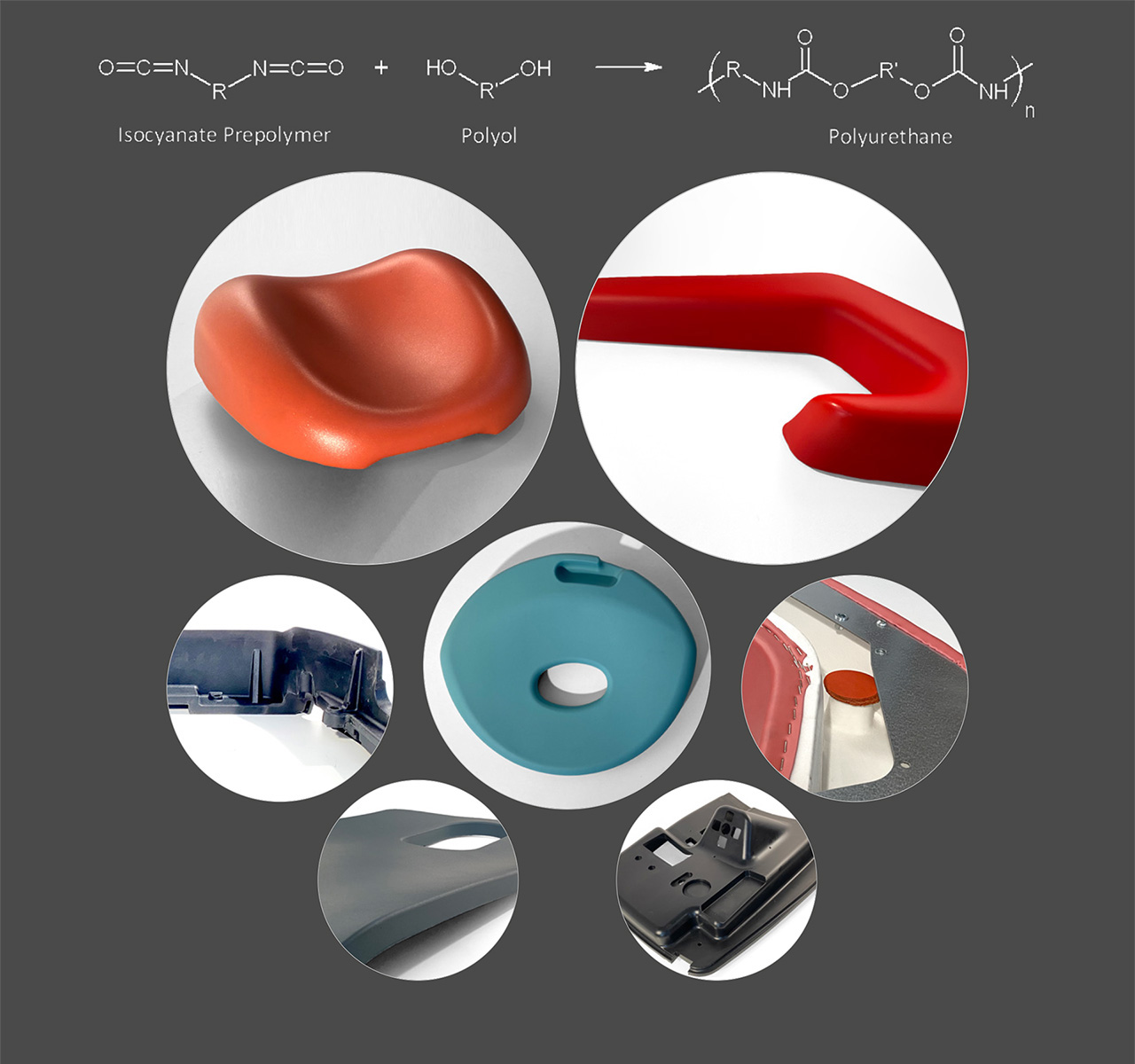

Rigid polyurethane is a material with high technical and aesthetic content.

Rigid and flexible moulded polyurethane applications are many and range from interior design, biomedical and dentistry, industrial design, lighting, beautician, fitness, to components for industrial and agricultural machinery.

DESIGN AND CONSTRUCTION OF INTERNAL STRUCTURES IN STEEL, THERMOPLASTIC MATERIAL OR WOOD

With the possibility of upholstery with multiple types of coating.

The polyurethane systems used have been specially formulated in collaboration with the world’s leading manufacturers to achieve the best performance for every needs and are certified according to the strictest standards for combustion, smoke emission and harmfulness.

THANKS TO MACHINERY OF THE LATEST GENERATION, EACH PRODUCT IS PRINTED WITH THE OPTIMAL MACHINE PARAMETERS

ISO-POL, weight, flow rate, emulsion, material temperatures and mould temperatures.

The entire production of flexible moulding is subjected to degassing through the use of an autoclave having the function of softening and homogenizing the rubber.